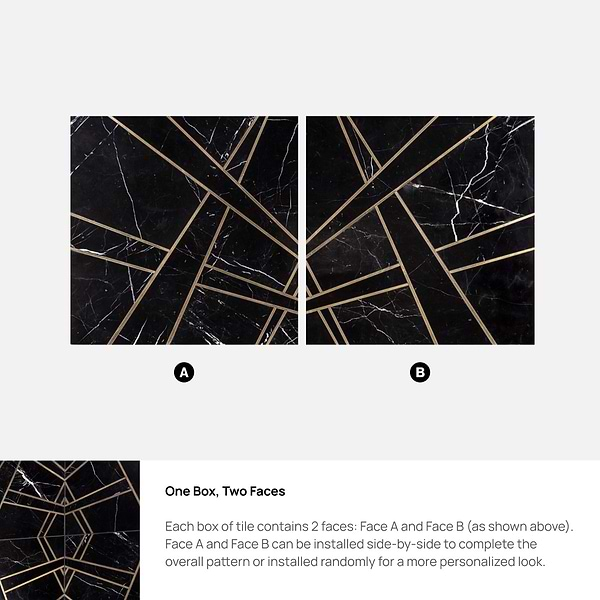

Empire Nero Black & Gold 24x24 Polished Marble & Brass Tile

$59.99 / sq. ft.

$69.95

Loading...

All samples ship for FREE when you order 5 samples or more! Samples typically ship within 1-3 business days.

For all regular priced non-sample orders, get fast, low-cost shipping, whether you're ordering one, one hundred, or one million square feet of tile. When you order from TileBar, you're ordering from the source. Most products are in stock in our NJ warehouse and ready to ship to your doorstep. Orders typically ship within 2-5 business days. Need it sooner? Expedited shipping options may be available at checkout.

* Additional charges apply for shipping to AK, HI, PR and the U.S. Virgin Islands.Charges may also apply to hard-to-reach areas such as military bases and locations only accessible via ferry. These charges will be assessed after your order is processed, and you will be contacted to provide payment for said charges. We will ship your order shortly after we receive payment from you.

Larger orders and delicate material, including most orders of porcelain tiles, may need to be shipped via freight carriers. The freight company may contact you to set up a delivery appointment. These orders will normally include curbside delivery only.

Did you order too many tiles, or were you not 100% satisfied with your purchase? No problem. TileBar is happy to accept returns within 180 days of your order. Please read the following information carefully.

1. You must request an RMA (Return Merchandise Authorization) form by emailing returns@tilebar.com.

2. Samples, clearance, FINAL SALE items, and custom orders are non-refundable.

3. In order for us to continue to be able to offer affordable pricing, a 15% restocking fee is assessed on all returns. Shipping charges are non-refundable. Customer are responsible for return shipping charges and arrangements.

4. All returns must be in their original packaging and in the condition in which they were received.

* Click here for more details.

Key Specs

- Color Black

- Commercial Wall, Floor

- Finish Polished

- Residential Wall, Floor

Finding its inspiration in the bright lights and bustle of the Empire State, the Empire Collection channels the attitude and affluence of New York City in all its glory. The distressed marble and chrome create an elegant look, curated for those looking to make an impact in their home or commercial space. Dramatic strips of brass set in Nero Marquina define this sophisticated pattern. Plus, this marble tile is backed by porcelain, reinforcing its shape and making it even more long-lasting. Showcasing true artisan beauty, the Empire Nero Marble & Brass Tile is the ideal statement piece.