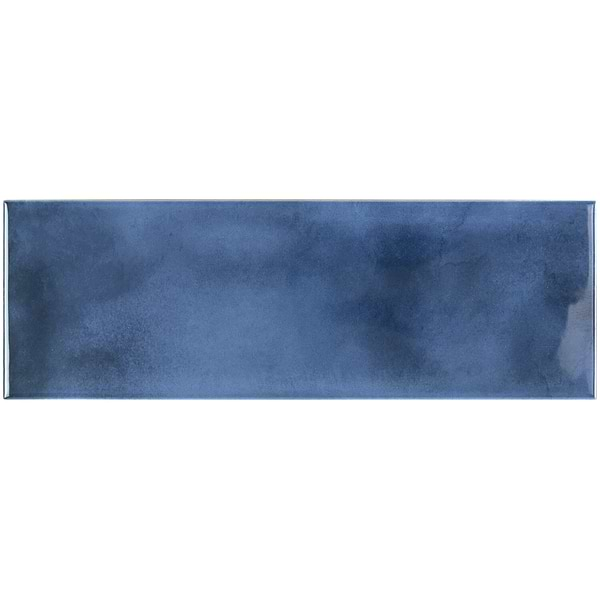

Diesel Camp Smoke Blue 4x12 Glossy Ceramic Subway Tile

Loading...

All samples ship for FREE when you order 5 samples or more! Samples typically ship within 1-3 business days.

For all regular priced non-sample orders, get fast, low-cost shipping, whether you're ordering one, one hundred, or one million square feet of tile. When you order from TileBar, you're ordering from the source. Most products are in stock in our NJ warehouse and ready to ship to your doorstep. Orders typically ship within 2-5 business days. Need it sooner? Expedited shipping options may be available at checkout.

* Additional charges apply for shipping to AK, HI, PR and the U.S. Virgin Islands.Charges may also apply to hard-to-reach areas such as military bases and locations only accessible via ferry. These charges will be assessed after your order is processed, and you will be contacted to provide payment for said charges. We will ship your order shortly after we receive payment from you.

Larger orders and delicate material, including most orders of porcelain tiles, may need to be shipped via freight carriers. The freight company may contact you to set up a delivery appointment. These orders will normally include curbside delivery only.

Did you order too many tiles, or were you not 100% satisfied with your purchase? No problem. TileBar is happy to accept returns within 180 days of your order. Please read the following information carefully.

1. You must request an RMA (Return Merchandise Authorization) form by emailing returns@tilebar.com.

2. Samples, clearance, FINAL SALE items, and custom orders are non-refundable.

3. In order for us to continue to be able to offer affordable pricing, a 15% restocking fee is assessed on all returns. Shipping charges are non-refundable. Customer are responsible for return shipping charges and arrangements.

4. All returns must be in their original packaging and in the condition in which they were received.

* Click here for more details.

-

$39.99

-

$27.95

-

$39.99

-

$27.95

-

$3,395.00 $2,380.00

Why You'll Love It

- 01Made In Italy

- 02Mix-Match glossy & crackled finishes To add depth

- 03Made for residential and commercial walls

- 04Great for kitchen, backsplash, bathroom, shower

Need an Expert?

Our all-inclusive Free Design Services are here for you. We match you with a personal Tile Design Consultant to help from design to delivery—for free. Details here

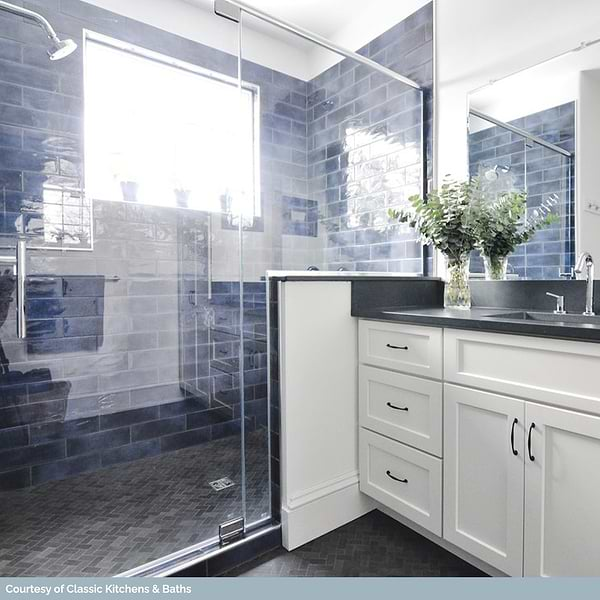

See It Installed

About The Collection: Powerful ideas with textures transposed from textiles, either reworked or accurately reproduced. The newest series in the Diesel Collection encompasses an assortment of unique compositions making this the most dynamic entry in the line to date. Available in multiple dynamic patterns perfect for mixing and matching, Diesel Camp flawlessly captures the aesthetic and inherent beauty of ceramic tile.

-

Key Features

- Made In Italy

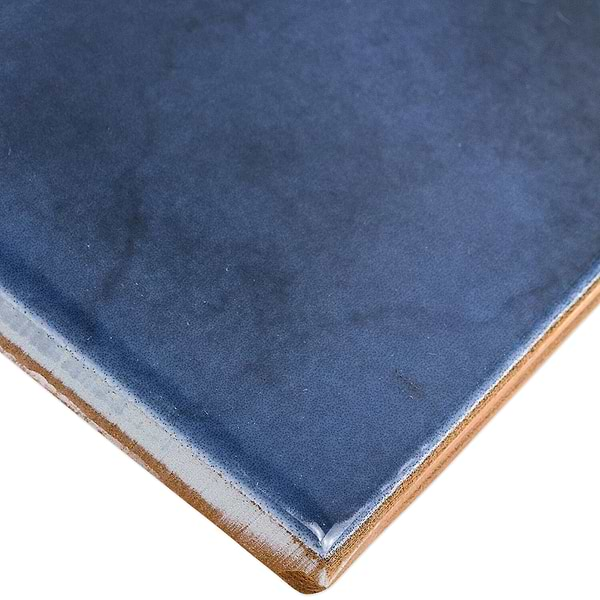

- 4x12" Glazed Ceramic Tile

- Classic Subway Look & Blue Colorway

- Made for Residential & Commercial Wall Use

- Great for Backsplash, Kitchen, Bathroom, Shower

Key Specs

-

Colorway

Blue

-

Commercial

Wall Only

-

Item Size

4" x 12"

-

Material

Ceramic

-

Residential

Wall Only

-

Tile Finish

Glossy

Detailed Specs

-

Available Sizes

4x12"

-

Breaking Strength

>700 N

-

Coverage

0.33

-

Frost Resistant

Yes

-

Location

Backsplash, Bathroom, Indoor, Kitchen, Shower

-

Look

Handmade Look

-

Made In

Italy

-

Outdoor Use

Outdoor Wall

-

Pieces Per Box

34

-

Recommended Grout Joint

1/18” min

-

Sq Ft Per Box

10.97

-

Style

Classic, Industrial, Mediterranean

-

Sustainability

LEED, EPD

-

Tile Thickness

7 mm

-

Tile Use

Backsplash, Bathroom Wall, Kitchen Wall, Shower Wall, Wall Tile

-

Water Absorption

<16%

-

Weight

30.1 lbs

Dimensions

-

Sample Size

3.9" x 11.6"

When installing ceramic or porcelain tiles or mosaics, make sure all your products, substrate, tile, thinset and grout are compatible with each other. Inspect all materials before use and getting started. Dry lay or do a mockup to confirm your layout, grout joint size and that the final look meets your expectations.

Download our installation guide here.

Download our care & maintenance guide here.

General Notes

- All installations should refer to the most current TCNA manual. Tile Council of North America 864.464.8453 Home - The Tile Council of North America (tcnatile.com)

- All TileBar installation instructions are suggestions. Specific installation questions should be brought to a local tile professional.

- Follow directions on all materials, especially mixing quantities.

- Inspect all materials before using to make sure there are no defects. Installation is acceptance, material claims will not be entertained after install.

- Blending different boxes of tile is recommended before and during installation.

- Ensure proper Safety – PPE (ex: Gloves)

-

$39.99

-

$27.95

-

$3,395.00 $2,380.00

-

$39.99

-

$27.95

-

$3,395.00 $2,380.00

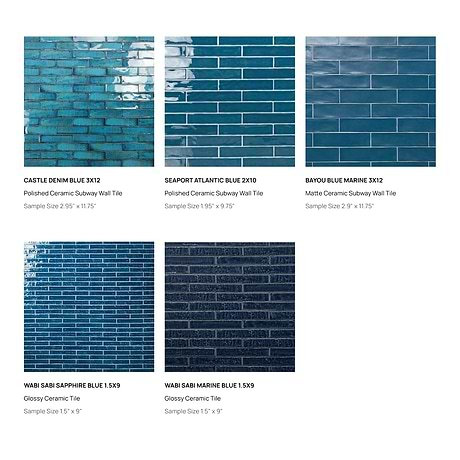

Recommended for You 1 of 10

-

$19.95 sq. ft. As low as $17.95

-

$8.95 sq. ft.

-

$9.95 sq. ft. As low as $8.95

-

$9.95 sq. ft.

-

$8.95 sq. ft. As low as $6.95

-

$5.00

-

$8.95 sq. ft. As low as $6.95

-

$11.50 sq. ft. As low as $10.35

-

$9.95 sq. ft. As low as $7.95

-

$9.95 sq. ft. As low as $7.99