Cause & Cure: A Guide To Addressing Large Porcelain Challenges

The NTCA Reference Manual is an important industry document that approaches challenges in the field from a problem/cause/cure format. The comprehensive culmination of knowledge, research, development and publication of the efforts of the NTCA Technical Committee addresses many problems that arise in the field, how to prevent them or address them when they occur. Today we look at the chapter on Large Porcelain and Glass Bodied Tiles, appearing in Chapter 6, page 124 in the 2016-2017 version.

The Problem, Defined.

Loss of bond between bond coat and large porcelain tiles or tiles containing high percentage of glass in the body. Tiles may come off mortar bond coat clean, even with full coverage on backs of tiles.

The Cause, Found.

• Inadequate contact between mortar bond coat and backs of tiles which may be caused by improper beat-in and using inadequate amounts of mortar, or worn or improper trowels.

• Use of pure cement bond coat over plastic mortar beds.

• Use of dry-set mortar without latex additives.

• Presence of excessive white powder (manufacturer’s release agent) on back of tile.

• Bending or deflection of substrates.

• Differential expansion between tile and setting material.

• Working on or too early traffic on newly-laid tile floors.

• Shrinkage or setting of substrates due to changes of moisture in structure or movements in the structure after construction is complete.

• Improperly engineered structure for the installation put into place.

The Cure.

Any of the following may prevent problems with large porcelain and glass-bodied tiles.

• To secure good contact between tiles and ribs of latex-Portland cement mortar, tiles must be pushed and slid into the mortar using NTCA recommendations for bedding tiles. Backbuttering tiles with a thin, flat coat of latex-Portland cement mortar helps develop a better bond to the tile.

• On large format tile, a box screen has proven to be an excellent means of controlling the amount of mortar applied to the back side of large tiles. Latex-Portland cement mortar applied to the substrate should be troweled out evenly in one direction – not swirled – with notched trowels. Ribbed mortar on only one surface helps reduce voids and air pockets. This method also produces a smoother, more even surface than conventional backbuttering, which often leaves tiles with excessive lippage.

• Successful installations of large porcelain and glass-bodied tiles require the use of a manufacturer’s recommended latex-Portland cement mortar that meets or exceeds ANSI specifications. Use latex-Portland cement mortars that are more flexible, in addition to having superior bonding capability. Latex-Portland cement mortars bond large porcelain tiles and tiles containing glass in the body, better than more conventional mortars. Mortar flexibility helps bridge stresses created between substrates and large, unforgiving tiles, reducing possibility of tiles shearing off. Check with manufacturer for exact products recommended.

• Press or slide tiles into position using NTCA recommendations for bedding tiles. Check to see that uniform contact is being achieved at corners, edges, and the back of the tiles by pulling tile up for examination. Beating-in only of larger tiles generally is not effective. Average contact area shall not be less than 80% except on exterior or wet area installations (see TCNA Handbook for wet area definition) where contact area shall be 95% when not less than three tiles or tile assemblies are removed for inspection.

• Check tiles for presence of excessive white powder (manufacturer’s release agent) on back of tile. If necessary, brush or remove white powder before attempting to bond tile.

• Porcelain tiles have extremely low water absorption rates. As a result, the setting time of many latex-Portland cement mortars may be extended. Therefore, working on or exposing the installation to traffic prior to a good bond forming may result in poor performance of the completed job.

• Proceed with caution when installing large porcelain tiles over substrates subject to bending or deflection. When installing materials with special or unique properties, the code minimum may not be sufficient to provide satisfactory performance. Each project presents its own conditions; consult with owner or builder to determine if any modifications to the structure can be done prior to the installation when you suspect problems or have concerns.

• Web floor trusses and engineered I-joists are used in ways that weren’t possible with traditionally sawn lumber. Be aware of the conditions you face prior to installation so adjustments can be made if necessary. See NTCA’s document on Installations over Engineered Wood Products for additional information.

• Require architect or construction manager to locate movement joints in tile work as recommended in the TCNA Handbook. Design, locations, spacing, and actual installation must conform to requirements in the TCNA Handbook and ANSI Standards. Movement joint recommendations apply to residential construction as well as commercial and industrial construction.

• When faced with installation of large porcelain tiles or tiles with glass in the body, insist on using latex-modified Portland cement mortars when they are not specified. Also, require mortar manufacturers to furnish test results showing bonding and flexural capabilities of mortars and bondability of tiles from tile manufacturers.

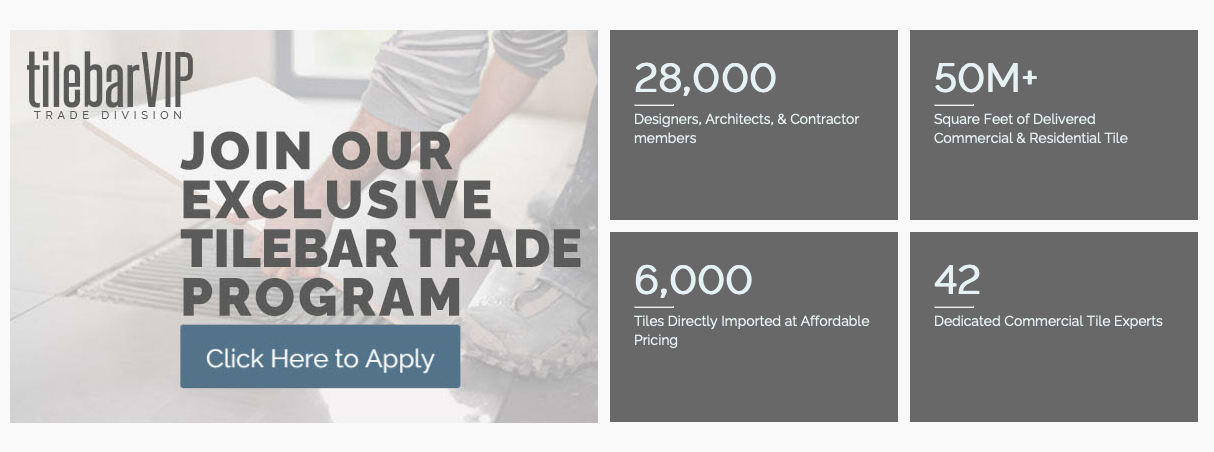

In the Interior Design world? Join our VIP Trade Program and you can enjoy a ton of perks like special discounts and volume pricing, to name a few.

Reprinted with permission from TileLetter May 2017 issue. Visit TileLetter.com for more information.