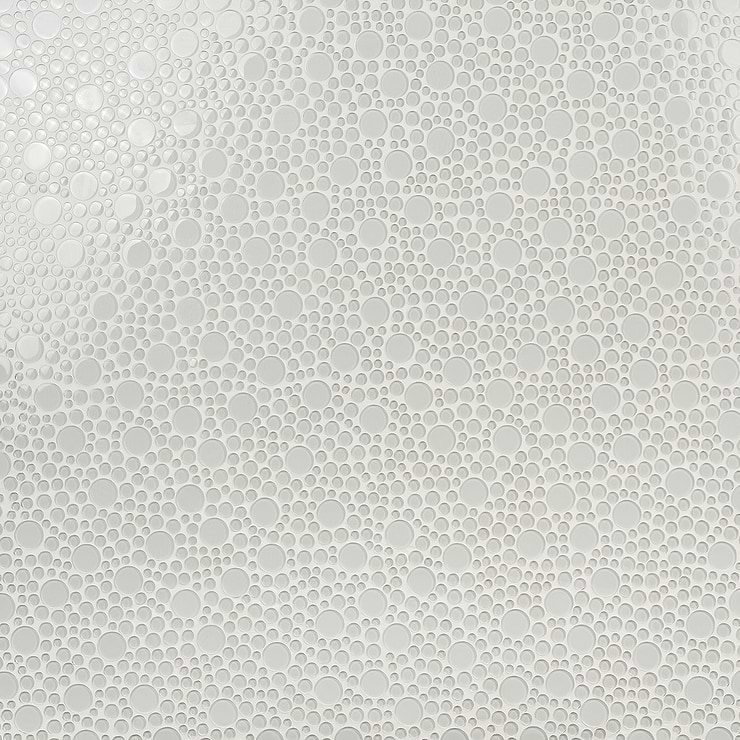

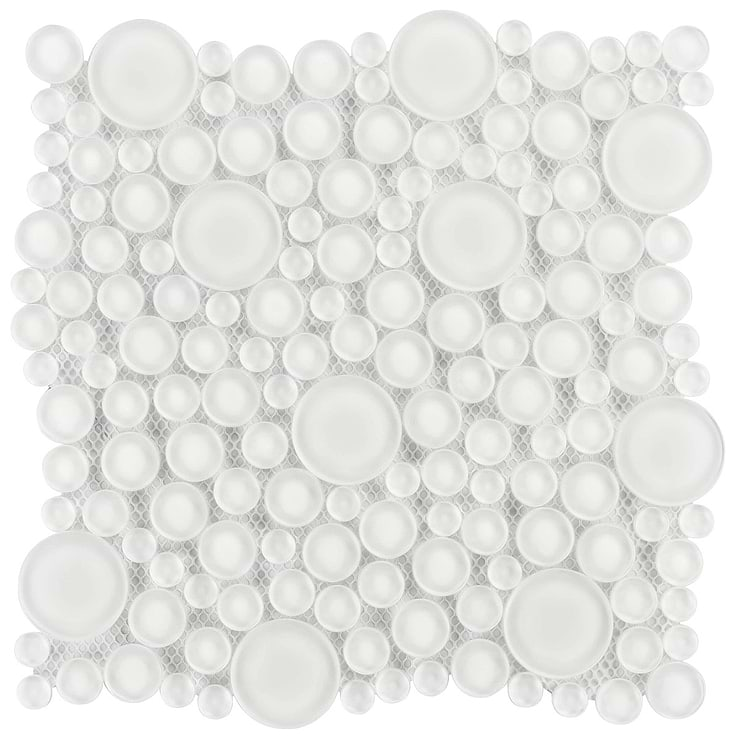

Loft Spa Super White Circles Glass Polished Mosaic Tile

Loading...

All samples ship for FREE when you order 5 samples or more! Samples typically ship within 1-3 business days.

For all regular priced non-sample orders, get fast, flat-rate shipping. Standard Shipping orders ship in 7-10 business days. Expedited Shipping orders placed before 2pm EST Monday-Thursday or Friday by 10:30am ship the same day. VIP Freight typically ships in 1-2 business days. Ordering from TileBar means you're ordering from the source. Most products are in stock in our warehouses and ready to ship to your doorstep. Our fast shipping means you should expect to receive your order within 7-10 days. Need it sooner? Expedited shipping options are available at checkout.

* Flat rate shipping does not apply to closeouts, specially priced orders, slabs or scrap lots. Additional charges apply for shipping to AK, HI, PR and the U.S. Virgin Islands.

* Click here for more details.

Did you order too many tiles, or not 100% satisfied with your purchase? No problem. TileBar is happy to accept returns within 365 days of your order. Please read the following information carefully.

1. You must request an RMA (Return Merchandise Authorization) form by emailing [email protected].

2. Samples, clearance, FINAL SALE items, and custom orders are non-refundable.

3. In order for us to continue to be able to offer affordable pricing, a 15% restocking fee is assessed on all returns. Shipping charges are non-refundable. Customer are responsible for return shipping charges and arrangements.

4. All returns must be in their original packaging and in the condition in which they were received.

* Click here for more details.

Why You'll Love It

- 01Circle polished glass tile

- 02Durable lasting beauty

- 03Made for residential and commercial walls

- 04Great for kitchen, backsplash, bathroom, shower

-

Light-as-air

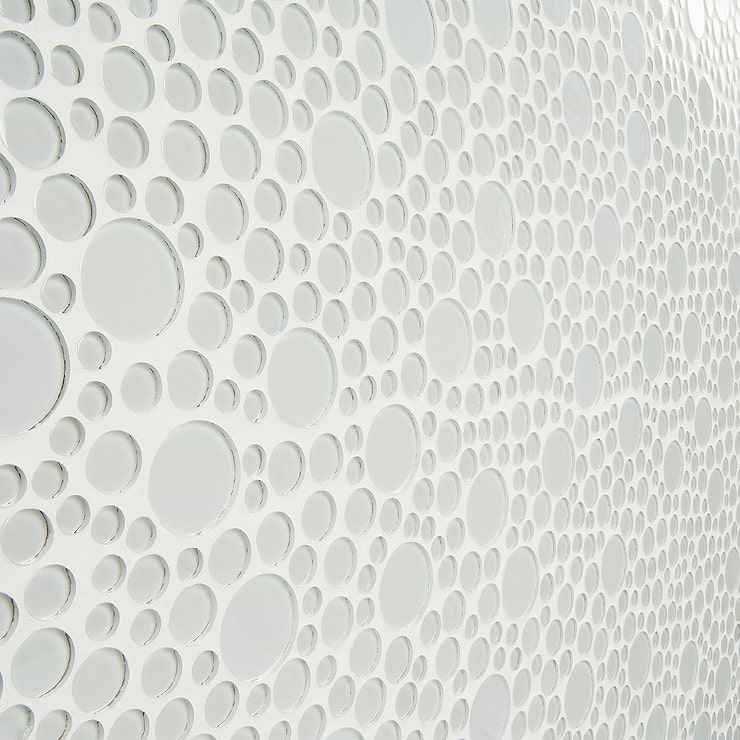

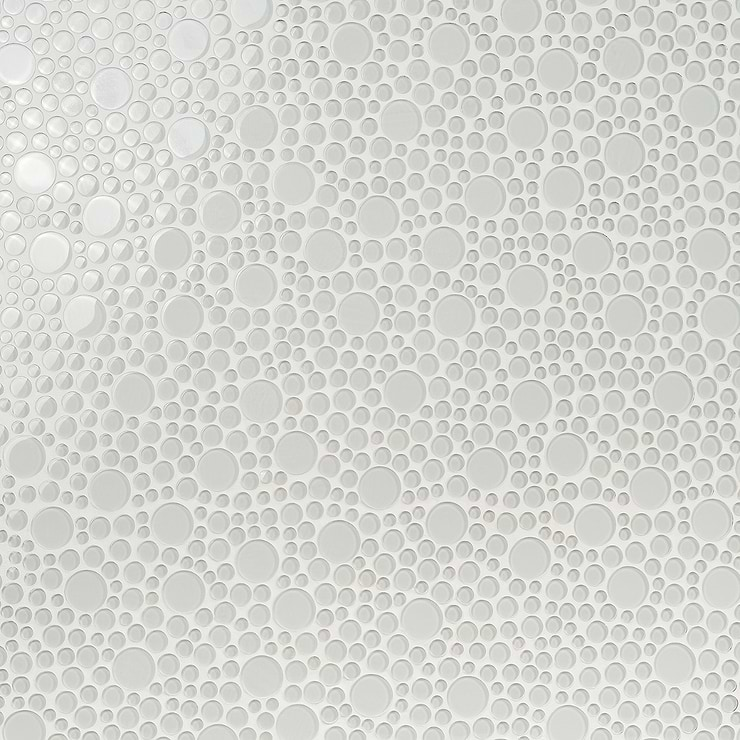

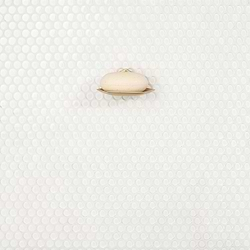

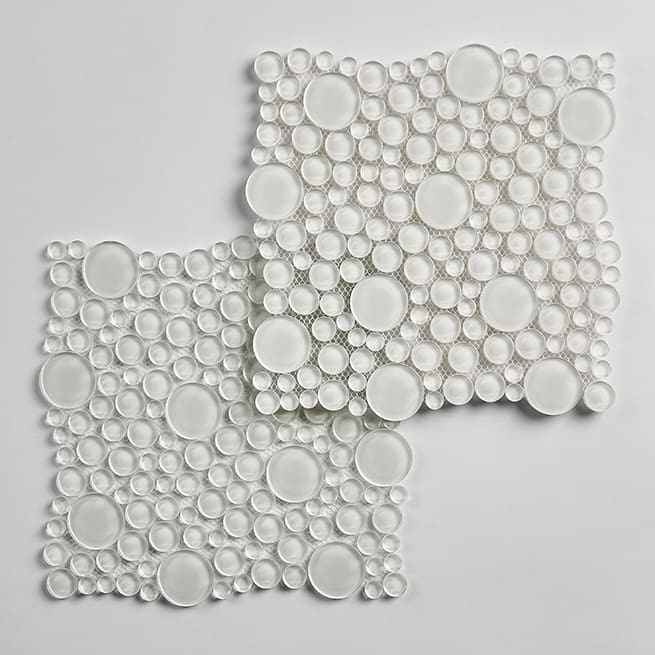

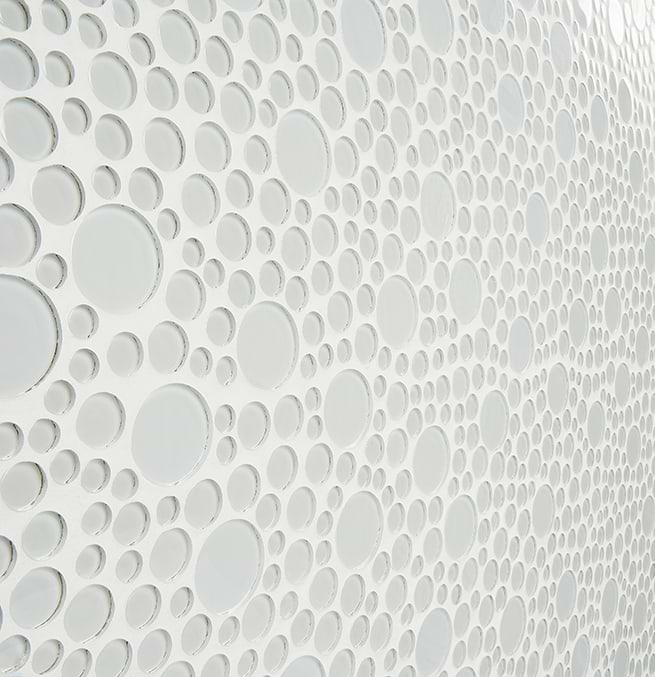

The Loft Spa Super White Circles Glass Polished Mosaic Tile gives the impression of delicate bubbles floating. Artfully scattered circular glass tiles mounted on a mesh-backed sheet mingle in a range of sizes. The color of this durable, heat- and water-resistant tile is painted on the back, ensuring it will look like new for years to come. The polished surface of this crisp white mosaic reflects light, making anywhere it is installed appear more spacious.Timeless style

Classic round and penny round motifs can be traced back several centuries.

Easily customizable

A mosaic format makes it easy to separate tiles for one-of-a-kind installations.

-

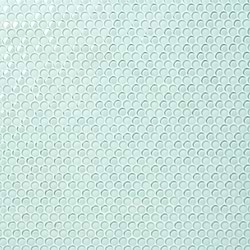

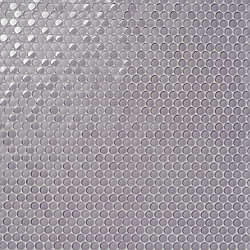

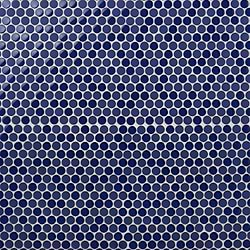

High gloss shine

Light reflects beautifully off the polished surfaces of the Loft Penny collection of glass mosaic tiles. Choose from a range of cheerful colorways or easy-to-style neutrals. The collection is available in rows of evenly sized, one-inch penny rounds or as multi-sized circular tiles in a scatter pattern—evoking the appearance of delicate bubbles. -

Glass: A naturally earth-friendly material

Each glossy tile in the Loft Penny collection is abraded to achieve its perfectly round shape. The glass is first cut into a small square and then put through a machine that slowly shapes the sides of the chips to form circles. The result is a stunning, one-of-a-kind glass mosaic that is both beautiful in the home and kind to our planet. Because glass is 100 percent and endlessly recyclable, it benefits everyone: consumers, manufacturers—and the environment.

Key Specs

-

Commercial

Wall Only

-

Item Color

White

-

Material

Glass

-

Residential

Wall Only

-

Tile Finish

Polished

Details

-

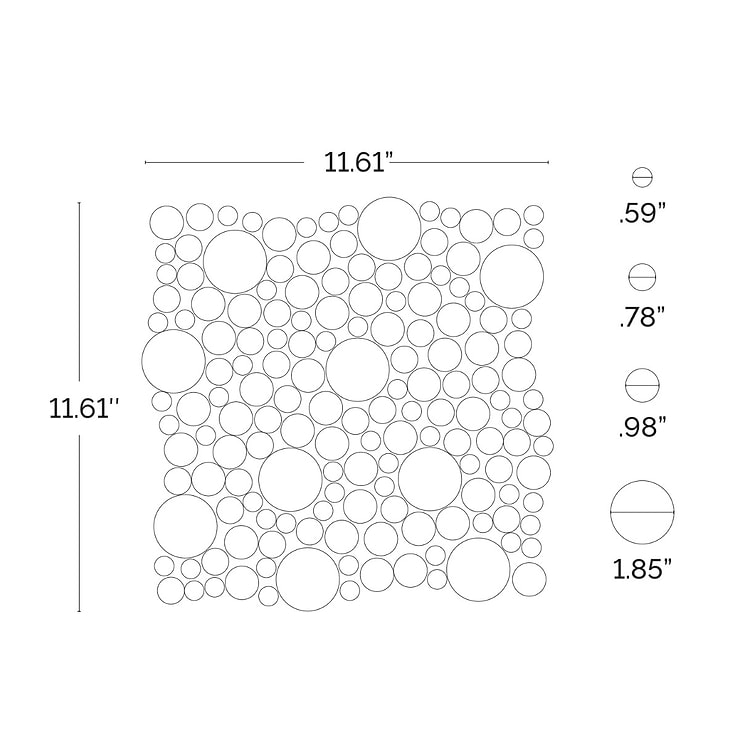

Available Sizes

1", 3/4", Mosaic

-

Coverage

0.92

-

Frost Resistant

Yes

-

Location

Backsplash, Bathroom, Indoor, Kitchen, Outdoor, Pool, Shower

-

Look

Solid Color

-

Outdoor Use

Exterior Wall

-

Pattern Shape

Circle

-

Recommended Grout Joint

1/8”

-

Sample Size

2.8" x 6"

-

Size

11.5" x 11.5"

-

Style

Beach, Contemporary

-

Thickness

8 mm

-

Tile Use

Backsplash, Bathroom Wall, Kitchen Wall, Outdoor Wall, Pool Tile, Shower Wall, Wall Tile

-

Weight

2 lbs

When installing glass tiles or mosaics, make sure all your products, substrate, tile, thinset and grout are compatible with each other. Inspect all materials before use and getting started. Dry lay or do a mockup to confirm your layout, grout joint size and that the final look meets your expectations.

Download our installation guide here.

Download our pool installation guide here.

Download our care & maintenance guide here.

General Notes

- All installations should refer to the most current TCNA manual. Tile Council of North America 864.464.8453 Home - The Tile Council of North America (tcnatile.com)

- All TileBar installation instructions are suggestions. Specific installation questions should be brought to a local tile professional.

- Follow directions on all materials, especially mixing quantities.

- Inspect all materials before using to make sure there are no defects. Installation is acceptance, material claims will not be entertained after install.

- Blending different boxes of tile is recommended before and during installation.

- Ensure proper Safety – PPE (ex: Gloves, Glasses)